In every industrial project, efficiency is the key to saving costs and maximizing output. While pumps and pipelines often take the spotlight, valves are the hidden components that make or break a system’s performance. Choosing the right valve does not just control flow—it improves energy efficiency, reduces downtime, and extends the life of your equipment.

Why Valve Efficiency Matters

A poorly selected or low-quality valve can lead to:

- Pressure losses and higher energy consumption

- Frequent leakage or sealing failures

- Unexpected downtime and costly repairs

- Safety risks in high-pressure or hazardous applications

By contrast, a properly chosen valve ensures smooth operation and long-term stability.

Valve Types That Drive Efficiency

Ball Valves

Quick shut-off and tight sealing make them ideal for oil, gas, and chemical industries. Their low flow resistance helps reduce energy waste.

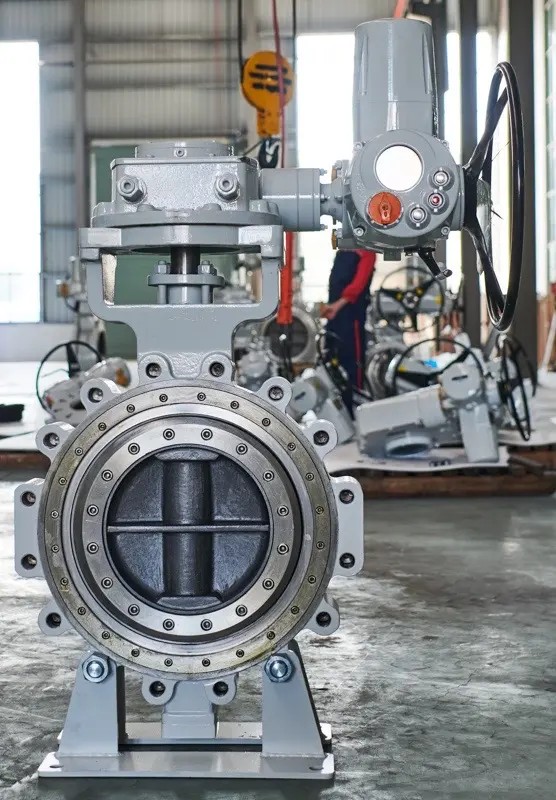

Butterfly Valves

Lightweight and cost-effective, perfect for water treatment and HVAC systems. Their compact design makes installation faster and cheaper.

Gate Valves

Full bore flow minimizes pressure drop, ensuring maximum throughput in oil & gas pipelines.

Globe Valves

Best choice when precise throttling is required, helping maintain stable process control.

Control Valves

Critical for automated systems in power plants and refineries, enabling accurate regulation of pressure and temperature.

How to Select the Most Efficient Valve

When choosing a valve, consider the following:

- Flow characteristics – Does your system need full flow or precise control?

- Operating conditions – Temperature, pressure, and type of medium.

- Maintenance requirements – Some valves are easier to maintain, reducing downtime.

- Automation compatibility – Pneumatic, electric, or smart control options.

A simple adjustment in valve selection can improve efficiency by reducing pump load and preventing energy losses.

Industry Applications

- Oil & Gas: Ball and gate valves ensure tight sealing under extreme conditions.

- Water Treatment: Butterfly valves offer a reliable yet affordable solution for large pipelines.

- Chemical Industry: Globe and control valves maintain precise flow control for sensitive processes.

- Mining & Wastewater: Knife gate valves handle slurry and solids without clogging.

Why Choose Us as Your Valve Partner

- Wide product range: Ball, butterfly, gate, globe, check, knife gate, solenoid, and control valves.

- Proven quality: Certified to API, CE, ISO, and fire-safe standards.

- Cost efficiency: Durable products designed to minimize energy and maintenance costs.

- Fast support: Professional quotation within 24 hours.

Final Thoughts

Valves may not be the biggest investment in your system, but they have one of the largest impacts on efficiency and safety. The right valve selection can save energy, reduce downtime, and ensure smooth operation for years to come.

📩 Looking for a reliable valve supplier? Send us your project specifications today, and our team will recommend the most efficient solution for your application.