January 4, 2026

Eric Jiang

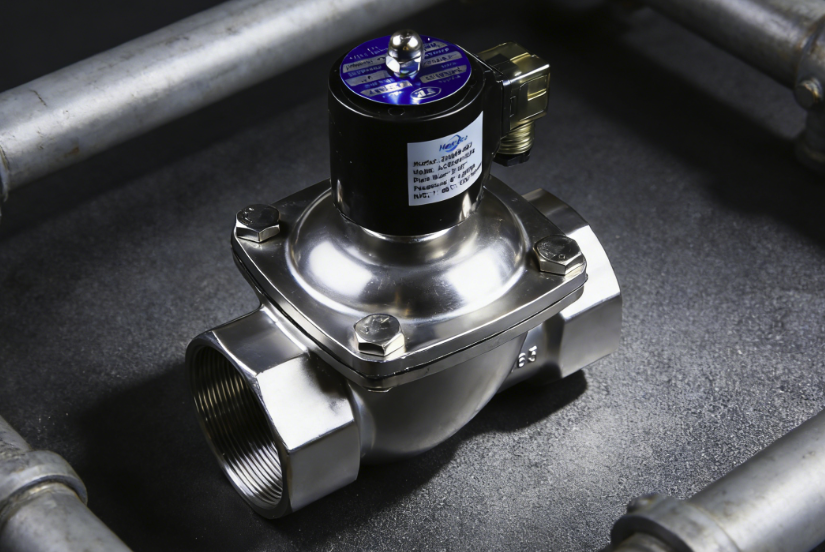

Solenoid valve

Steam solenoid valves are easy to buy and expensive to buy “twice.” Many failures happen because key selection details are missing during purchasing—especially pressure conditions, condensate risk, coil temperature limits, and installation requirements.

This one-page checklist is designed for buyers, engineers, and maintenance teams to quickly confirm the correct steam solenoid valve before placing an order.

1. Steam System Basics (Must Fill In)

Before selecting a valve, confirm these operating conditions:

- Steam type: saturated steam / slightly superheated / unknown

- Normal pressure: ____ bar

- Maximum pressure: ____ bar

- Minimum pressure: ____ bar

- Steam temperature: ____ °C

- Flow requirement (load): ____ kg/h (or describe equipment size)

- Inlet pressure stability: stable / fluctuating

- Back pressure at outlet: low / medium / high / unknown

If minimum pressure or back pressure is unknown, pilot-operated valves can easily be selected incorrectly.

2. Valve Function (Safety Decision)

Choose the correct action type:

- Normally Closed (NC) (recommended for most steam systems)

- Closes on power loss → safer against uncontrolled steam release

- Normally Open (NO)

- Only if required by special safety logic or process design

For industrial steam lines, NC is usually the correct default.

3. Valve Design (Direct-Acting vs Pilot-Operated)

This decides whether the valve will open reliably.

Choose Pilot-Operated if:

- Steam pressure is stable

- You need medium/large flow capacity

- You can meet minimum differential pressure (ΔP)

Choose Direct-Acting if:

- Pressure is low or unstable

- You suspect low ΔP conditions

- Pipe/orifice is small and reliability is the priority

Buyer warning: If a pilot-operated valve cannot meet minimum ΔP, it may not open, may chatter, or may fail early.

4. Body Material (Steam Reality Check)

Recommended:

- Stainless steel (best overall for steam + condensate corrosion + long life)

Sometimes acceptable:

- Brass for mild, intermittent steam and lower stress conditions (site-dependent)

If your steam is continuous, high temperature, or corrosive, stainless steel is the safer long-term choice.

5. Seal / Seat Selection (Don’t Guess)

Recommended for most steam:

- EPDM (high-temperature grade)

Consider:

- PTFE if chemical compatibility or low contamination is critical

- Metal seat for harsh/dirty/high-temperature steam and heavy cycling (may not be bubble-tight depending on design)

Avoid for continuous steam:

- NBR (hardens quickly in steam)

6. Cv / Flow Capacity (Avoid Oversizing)

To prevent chattering, water hammer risk, and unstable control:

- Select Cv based on real steam load, not just pipe size

- Avoid “one size bigger for safety”

Oversized valves often cause:

- unstable cycling

- chattering

- seat damage and leakage

7. Coil and Electrical Specs (Common Failure Point)

Confirm:

- Voltage: 24VDC / 110VAC / 220VAC / other

- Frequency: 50/60 Hz (for AC)

- Duty: continuous duty (recommended for steam control)

- High-temperature coil: required if installed near hot piping or enclosed areas

- IP protection: important in humid steam rooms

- Connector type: sealed connector + proper cable gland

If coils burn out often, the issue is usually ambient heat + mounting + voltage stability, not “bad coil quality.”

8. Installation Accessories (Must Specify on Purchase Order)

To protect the valve and ensure long service life, specify:

- Y-strainer upstream (protects pilot holes and seat)

- Drip leg + steam trap near the valve (prevents condensate impact)

- Coil mounted upright whenever possible

- Correct flow direction (arrow on body)

Buying the valve without these supporting items often leads to early failure.

9. Hazardous Area Requirements (If Applicable)

If the installation is in a classified area:

- Explosion-proof / hazardous location certification required? Yes / No

- Gas/vapor or dust? Gas / Dust

- Required temperature class and site classification (as per plant standard)

Explosion-proof is an electrical compliance requirement—it does not replace steam-rating requirements.

10. Final Pre-Order Questions (Fast Approval Test)

Before placing the order, answer:

- Can we meet minimum ΔP (if pilot-operated)?

- Do we have proper condensate drainage near the valve (trap + drip leg)?

- Is a Y-strainer included upstream?

- Is the coil rated for high ambient temperature in steam areas?

- Is the valve properly sized (not oversized)?

- Is the seal material correct (EPDM high-temp for most steam)?

If any answer is “No” or “Unknown,” fix that first—otherwise failures repeat.

Final Thoughts

A steam solenoid valve selection is not only a valve choice—it’s a system reliability decision. This checklist helps you avoid the most common purchasing mistakes and dramatically reduce leakage, chattering, coil burnout, and water hammer damage.

If you want the next blog post, I can write:

- Steam trap selection guide (disc vs F&T vs thermostatic with examples)

- How to calculate steam flow for valve sizing (simple buyer-friendly method)

- Steam solenoid valve maintenance plan (inspection points and service intervals)